In the competitive food industry, packaging is more than just a container for products; it’s a marketing tool, a protective barrier, and a reflection of a brand’s identity. Custom sleeve packaging has emerged as a versatile and cost-effective solution that meets the diverse needs of food manufacturers and retailers. Here’s why custom sleeve packaging is becoming a go-to choice in the food sector:

1. Enhanced Branding Opportunities

Custom sleeve packaging allows businesses to showcase their brand identity effectively. With the ability to print logos, vibrant colors, and engaging designs, companies can create a memorable unboxing experience for consumers. This not only increases brand recognition but also fosters customer loyalty.

2. Cost-Effective Solution

Compared to full box packaging, custom sleeves are more economical as they use less material while still offering ample space for branding and product information. This makes them an ideal choice for small and large-scale food businesses looking to optimize their packaging budget.

3. Eco-Friendly Option

Custom sleeves are often made from recyclable materials, aligning with the growing consumer demand for sustainable packaging. By using eco-friendly sleeves, companies can reduce their environmental impact and appeal to environmentally conscious customers.

4. Versatility

Custom sleeves can be designed to fit various types of food products, from frozen meals to bakery items. Their adaptability makes them suitable for diverse applications, ensuring that products remain secure and visually appealing.

5. Product Protection and Visibility

Sleeves provide an additional layer of protection to food trays or containers, keeping the product intact during transit and storage. They also offer a partial view of the product, which is especially useful for items where visual appeal influences purchasing decisions, such as pastries or fresh produce.

What is the Paper Tray Advantage?

Paper trays are becoming increasingly popular in the food industry due to their numerous advantages:

1. Sustainability

Paper trays are biodegradable and recyclable, making them an eco-friendly alternative to plastic trays. Their use helps reduce the environmental footprint of packaging, which is a significant concern for consumers and regulators alike.

2. Lightweight and Durable

Despite being lightweight, paper trays are sturdy and can hold various food items securely. Their durability ensures that food products remain intact during handling and transportation.

3. Heat Resistance

Many paper trays are designed to withstand high temperatures, making them suitable for oven-ready or microwaveable food products. This adds convenience for both manufacturers and end-users.

4. Customizability

Paper trays can be easily customized with branding, designs, and product information. This enhances their utility as a marketing tool while maintaining their functional benefits.

5. Cost-Effectiveness

Paper trays are often more affordable than their plastic or metal counterparts, especially when produced in bulk. This makes them a practical choice for businesses looking to manage costs without compromising on quality.

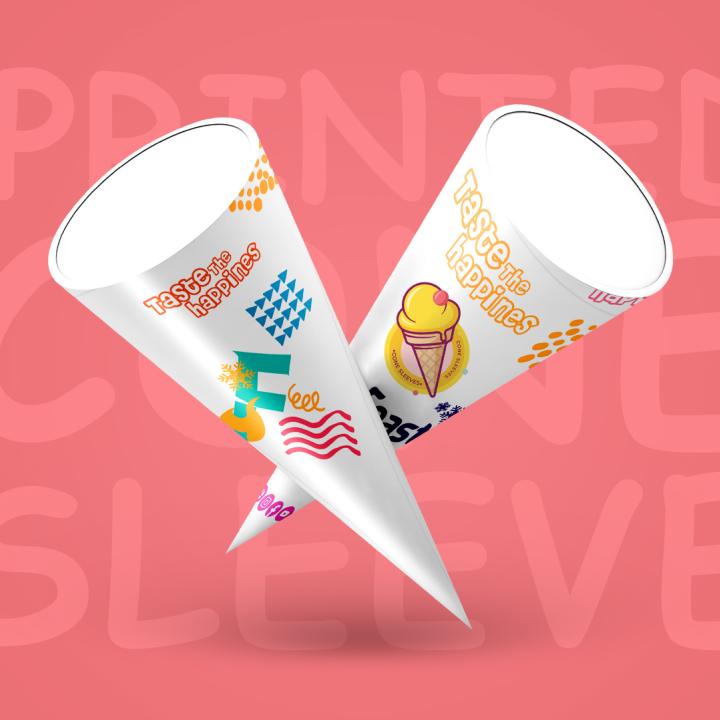

Which Material is Best for Cone Sleeves?

Cone sleeves are essential for providing a hygienic and convenient way to serve ice cream cones, waffles, or similar products. The choice of material plays a critical role in their effectiveness. Here are the top materials for cone sleeves:

1. Food-Grade Paperboard

Food-grade paperboard is the most commonly used material for cone sleeves. It is lightweight, sturdy, and safe for direct food contact. Additionally, it is easy to print on, allowing for vibrant and attractive designs.

2. Kraft Paper

Kraft paper cone sleeves is an eco-friendly option known for its natural and rustic appearance. It is biodegradable, recyclable, and strong enough to hold cones securely. Kraft paper is ideal for brands emphasizing sustainability.

3. Aluminum Foil-Lined Paper

For products that require added insulation, aluminum foil cone sleeves-lined paper is an excellent choice. This material helps maintain the temperature of the cone’s contents, ensuring a pleasant eating experience for customers.

4. Coated Paper

Coated paper is treated with a thin layer of plastic or wax, making it grease-resistant and moisture-proof. This is particularly useful for preventing leaks or stains, ensuring a clean and convenient handling experience.

Conclusion Custom sleeve packaging, paper trays, and cone sleeves are essential components of modern food packaging. Each offers unique benefits that cater to the needs of food businesses and consumers alike. By choosing the right materials and designs, companies can enhance their brand image, meet sustainability goals, and deliver a superior customer experience.