Rise

of Aluminum as Preferred Material

Aluminum has emerged as one of the most widely used metals in the world due to

its attractive properties such as light weight, corrosion resistance, and

recyclability. It has effectively replaced traditional metals in many

applications and continues to gain ground in new areas. The automotive and

construction industries have led the adoption of aluminum to reduce weight and

meet sustainability objectives. Aluminum extrusions, in particular, offer

architects and engineers greater design flexibility compared to other

manufacturing processes.

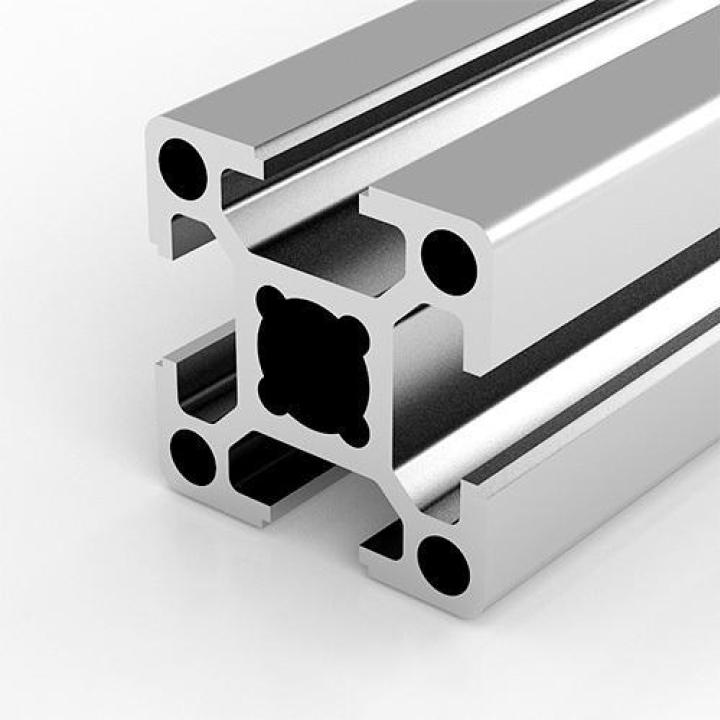

What is Aluminum Extrusion?

Aluminum extrusion is a process used to create objects of a fixed

cross-sectional profile. In this manufacturing process, rectangular aluminum

ingots are loaded into a hydraulic press and pushed through a pre-formed die.

The die gives the metal its final shape by sizing and shaping it as it is being

pushed from the container (billet) into a continuous profile. This allows for

the creation of intricate aluminum profiles with very tight tolerances.

Extruded parts have excellent mechanical properties and consistency along their

entire length.

Automotive Leads Growth in Extrusion

The automotive industry has hugely benefited from weight reduction using Aluminium

Extrusion. Nearly 30% of the weight of passenger cars manufactured

today comes from wrought aluminum. Automakers extensively use extrusions to

produce pillars, frames, suspensions, wheels, and other structural and interior

components. This has helped lower vehicle weight by 100-250 lbs on average,

significantly improving fuel efficiency. Even trucks and commercial vehicles

are now specifying more aluminum extrusions. With tighter emission regulations

worldwide, this extrusion growth in the automotive sector is projected to

remain strong.

Construction Sector Demand on the Rise

In construction, aluminum extrusions are finding wide application as frames for

windows, doors, railings, roofing, and siding. Their corrosion resistance,

durability, and low maintenance have made them a preferred choice compared to

wood in recent times. They provide solid, leak-proof frames that last the

lifetime of the building without issues like wood rotting or rusting.

Infrastructure projects also employ extruded aluminum for bridges, transmission

towers, seismic applications, and more. Major reconstruction activities across

regions are contributing to growth in construction extrusion demand.

Extrusion Dies - Enabling Complex Shapes

The heart of the extrusion process lies in the sophisticated extrusion dies

that form the heated aluminum into an endless variety of shapes. Recent

advancements in die-design and related tooling technologies have allowed

producers to create previously impossible three-dimensional shapes, intricate

hollow sections, and intricate tolerances less than a millimeter. This has

expanded the applications potential for extrusions. Investment in die

fabrication facilities and R&D continues to make extrusions an adaptable

process for intricate, tailored-solutions. Complex hydroformed tubular

components are also now possible using multi-step processes.

Innovation Drives New Applications

As extruded aluminum profiles deliver added abilities to designers, an array of

innovating applications emerge. Examples include electronic enclosures, medical

equipment housings, bicycle frames, playground structures, irrigation systems,

and outdoor furniture— areas where aluminum excels. Extrusions also find use in

renewable energy technologies. Solar panel frames, wind turbine towers, and

hydroelectric plant components benefit from aluminum’s durability, corrosion

resistance and light weight. With a dedicated focus on R&D, production

technology upgrades and quality control, its companies continue to tap new

opportunities across industries.

Focus on Sustainability

Environmental consciousness is driving increased recycling and green practices

in aluminum extrusion. Companies strive to manufacture extrusions using

produced from recycled scrap metal. The energy intensity of primary aluminum

production makes extrusion from recycled sources highly beneficial. Initiatives

to reduce waste and carbon footprint during extrusion manufacturing are also

gaining prominence. As public and private stakeholders emphasize

sustainability, its producers will face growing demands to comply with

eco-friendly standards throughout product lifecycles. Those that drive

sustainability performance stand to gain a competitive edge in the long run.

Explore More About Aluminium Extrusion

Choose

your Preferred language for better understanding-

About Author-

Ravina Pandya, Content Writer, has a strong foothold

in the market research industry. She specializes in writing well-researched articles

from different industries, including food and beverages, information and

technology, healthcare, chemical and materials, etc. With an MBA in E-commerce,

she has an expertise in SEO-optimized content that resonates with industry

professionals. (https://www.linkedin.com/in/ravina-pandya-1a3984191)