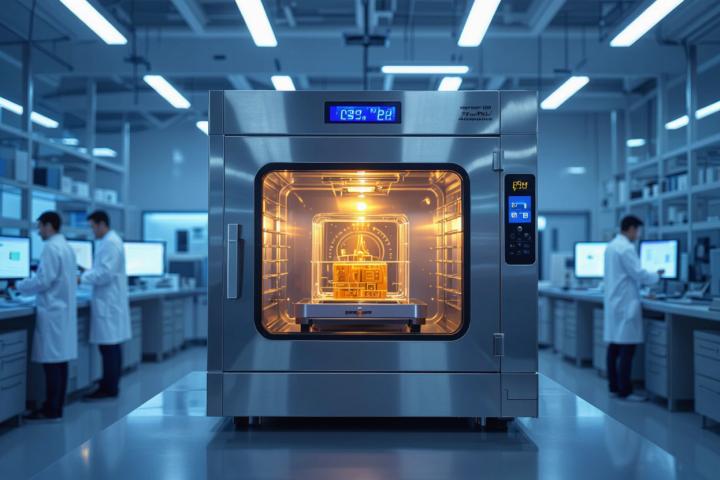

In the plastic products industry, the Double Color Injection Molding Machine, with its high efficiency and flexibility, has become the core technical equipment in the field of multi-color injection molding. This article will comprehensively analyze how this equipment promotes industrial upgrading from the aspects of technical principles, application scenarios, and industry advantages.

Technical Definition of the Double Color Injection Molding Machine

The double color injection molding machine is a professional equipment that realizes the layered injection molding of multi-color materials through a rotating shaft or turntable structure. Its core lies in accurately stacking two or more colors of plastic raw materials within the same production cycle by rotating the mold or turntable, achieving the integrated molding of complex structures. Compared with traditional single-color injection molding processes, this technology can significantly reduce production steps while enhancing the appearance and functionality of products.

Core Application Areas

The double color injection molding technology of the rotating shaft is widely applied in the manufacturing of products that require color differentiation or functional layering, such as:

Sports Equipment and Tool Accessories: For example, bicycle handlebar covers and fitness equipment handles can improve anti-slip performance and aesthetics through double-color overmolding.

Consumer Electronics Components: Including buttons, handles, etc., the double-color process is used to achieve seamless integration of logos and the base body.

Medical and Daily Necessities: Such as toothbrush handles and protective tools, the ergonomic performance is improved through different materials.

In these application scenarios, the equipment can support fully automated production, and only one person is required to supervise a single machine, greatly reducing labor costs.

Analysis of Technical Advantages

Efficient Production Mode

The double color injection molding machine with a rotating shaft adopts a turret or rotating shaft structure, and the mold can rotate 180 degrees to switch the injection molding stations, realizing the continuous molding of double-color or even triple-color products. Some models support flexible action timing control, such as giving priority to mold ejection or rotating the mold first, to meet the needs of different products.

Precision Control System

The equipment is equipped with branded linear potentiometers and a numerical control system, ensuring uniform material distribution and stable molding. Some manufacturers achieve standardized processing of core components through CAD/CAM technology, further enhancing the reliability of the equipment.

Energy Conservation and Compatibility

The rotating shaft design reduces the frequency of mold replacement, and is compatible with complex geometric shapes such as tubular and piercing structures, significantly reducing energy consumption and material waste.

Here is the Product Display Video!

Industry Development Trends

With the growth of the consumer market's demand for personalized products, the double color injection molding technology of the rotating shaft is evolving towards intelligence and modularization. For example:

Realize remote monitoring and fault warning through Internet of Things (IoT) technology.

Combine with precision equipment such as five-axis machining centers to improve the accuracy of mold manufacturing.

Develop a turntable system with expandable stations to support multi-layer injection molding of three or more colors.

Key Considerations for Selecting Equipment

When enterprises purchase a double color injection molding machine with a rotating shaft, they need to focus on:

Process Adaptability: Select a rotating shaft or turret model according to the product structure (such as tubular overmolding, piercing parts).

Stability of the Control System: Give priority to equipment with linear potentiometers and closed-loop control.

Technical Strength of the Manufacturer: Examine the processing capabilities (such as CNC machine tools, composite processing equipment) of suppliers and industry cases.

Conclusion

As a benchmark technology in the field of multi-color injection molding, the double color injection molding machine with a rotating shaft provides an efficient and precise solution for the manufacturing industry through the combination of innovative mechanical structures and intelligent control systems. With the deep integration of technological iteration and market demand, this equipment will continue to lead the industry towards products with high added value.

If you want to know the details of specific models, you can contact HONLED, and we will provide you with detailed answers!