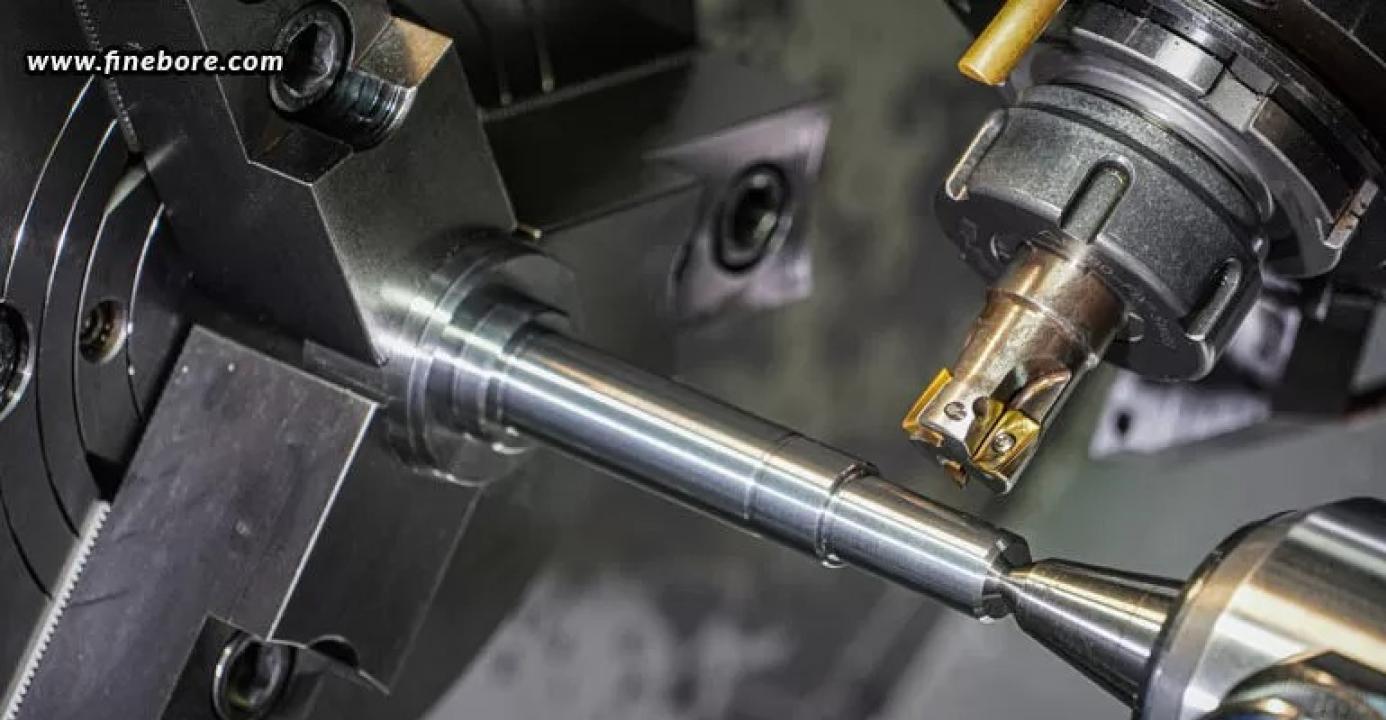

In precision machining, even minimal vibrations can result in inaccuracies, subpar surface finishes, and diminished tool longevity. As industries increasingly require tighter tolerances and enhanced finishes, effective vibration management has emerged as a vital component of machining success. This article delves into the origins of vibrations, their impact on machining operations, and contemporary strategies to mitigate them, thereby enhancing accuracy and efficiency.

Identifying the sources of vibration in machining

Machine tool instability: Instability in machine tools is a major contributor to vibration. Factors such as degraded bearings, loose parts, and improper installation can lead to excessive movement. The structural rigidity of the machine is crucial in absorbing vibrations, thereby ensuring stability and precision during machining tasks.

Resonance and chatter: Chatter occurs when the natural frequency of the machine-tool system aligns with external vibration frequencies, resulting in amplified oscillations. This self-induced vibration can lead to inferior surface quality and potential damage to tools and machinery.

Workpiece material characteristics: The properties of the material being machined also affect vibration levels. Harder materials necessitate greater cutting forces, increasing the potential for vibrations, while softer materials may yield under tool pressure, leading to instability.

Cutting forces and tool-workpiece interaction: Vibrations are generated by cutting forces as the tool interacts with the workpiece during machining. These vibrations can be exacerbated by variables such as tool overhang, feed rate, and spindle speed. The dynamics between the tool and workpiece significantly influence the overall stability of the machining process.

Clamping problems with tool holders and workpieces: Inadequate clamping of tools and workpieces can result in unintended movement, leading to chatter and surface imperfections. The selection of tool holders, collets, and work-holding devices plays a crucial role in minimizing vibrations.

Effects of vibration on machining performance

Diminished dimensional precision: Excessive vibration can cause deviations from the intended specifications, adversely impacting the accuracy of the final product. Precision machining requires tolerances at the micron level, which become challenging to maintain in the presence of vibrations.

Inferior surface quality: Vibrations occurring during the machining process can produce uneven surface textures, resulting in rough finishes that necessitate further post-processing. This not only extends production time but also increases costs.

Increased tool wear and risk of breakage: Uncontrolled vibrations can lead to excessive heat and stress on cutting tools, which accelerates wear and heightens the likelihood of tool breakage. This ultimately shortens tool lifespan and elevates operational costs.

Reduced efficiency: To mitigate the effects of vibrations, manufacturers are often compelled to decrease cutting speeds and feed rates, which results in longer machining cycles and diminished overall productivity.

Best practices for vibration management in machining

Employing precision boring tools: For machining tasks that demand high precision, utilizing top-quality boring tools equipped with built-in damping mechanisms ensures stability. FineTech Toolings offers precision boring tools in Bangalore specifically designed to minimize vibrations while achieving tight tolerances.

Ensuring proper tool configuration: Minimizing tool overhang, utilizing balanced tool assemblies, and selecting suitable tool holders enhance rigidity and stability throughout the machining process.

Improving workpiece clamping: Effectively securing the workpiece with high-quality clamps, vacuum chucks, or magnetic holding systems is vital to prevent movement and vibrations during machining operations.

Choosing appropriate cutting parameters: Optimizing spindle speed, feed rate, and depth of cut is essential for minimizing vibrations. Employing stability lobes to determine ideal cutting conditions can significantly improve machining efficiency.

Conducting regular machine maintenance: Maintaining machine components such as bearings, belts, and spindles in optimal condition is crucial for reducing vibration sources. Regular inspections and alignments are necessary to uphold accuracy.

Effective vibration management is essential in precision machining, influencing accuracy, tool longevity, and overall productivity. By recognizing the origins and impacts of vibrations, manufacturers can adopt advanced damping technologies, optimized machining practices, and high-quality tooling solutions to improve performance. As machining technology evolves, vibration management will remain a critical factor in achieving enhanced precision and efficiency in manufacturing.

Resource: Read more