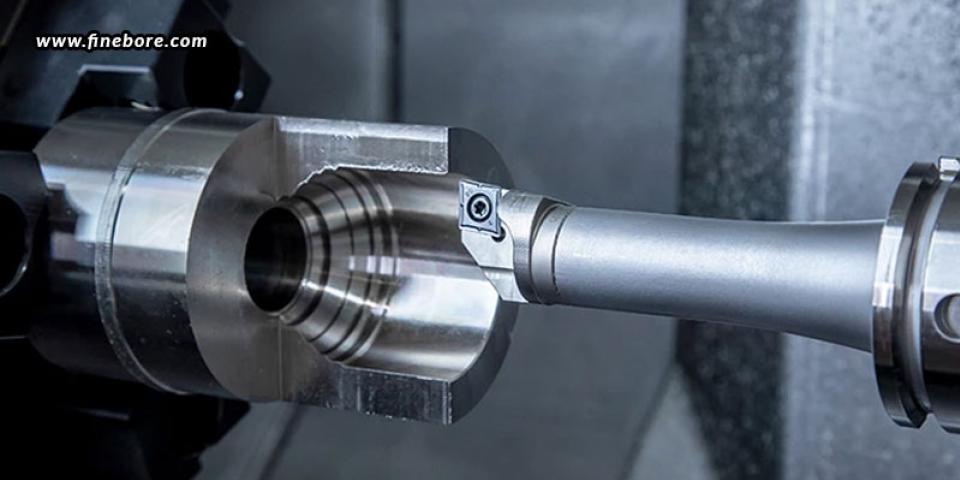

Boring tools are essential to attaining precise dimensions and perfect finishes, making them the foundation of precision machining. However, because of the rigorous conditions of machining operations, these tools are susceptible to wear and strain. Understanding typical wear issues, their fixes, and efficient tool life management techniques is essential to preserving high performance and extending their service life. This blog thoroughly examines these elements and offers helpful advice for maximizing the performance of boring tools.

Understanding common wear issues in boring tools

During machining, friction, heat, and material resistance cause several kinds of wear on boring tools. Early detection of these problems helps guarantee constant performance and avoid expensive downtime.

Flank wear: When the cutting edge of the tool and the workpiece come into constant contact, friction is created that erodes the tool’s surface over time. Harder tool materials like carbide or CBN can be used to improve wear resistance in order to counteract this. In order to keep excessive wear from affecting the quality of the machining, regular inspection and prompt tool replacement are crucial.

Crater wear: The contact of chips with the tool’s rake face causes crater wear, which can erode the cutting edge and cause craters. This problem is successfully resolved by applying cutting-edge coatings, such as diamond or titanium aluminium nitride (TiAlN), which improve surface hardness and reduce friction.

Built-up edge: Poor surface finish and tool performance result from material adherence on the cutting edge, which creates a built-up layer known as built-up edge (BUE). To reduce BUE development and preserve tool efficiency, use tools with anti-adhesion coatings, increase cutting speed, or use proper coolant.

Chipping and fractures: High cutting forces, heat stress, or vibrations that induce abrupt damage to the tool edge can result in chipping and fractures. Effective methods to lessen this issue include using vibration-dampening boring bars, fine-tuning cutting parameters, and making sure there is enough cooling during boring.

Thermal wear: Excessive heat during machining causes thermal wear, which accelerates tool degradation and softens the material. Reducing cutting speeds and using cooling systems or high-performance cutting fluids are essential steps in controlling heat generation and extending tool life.

Proactive strategies for tool life management

The use of high-quality tools, optimal machining techniques, and routine maintenance all contribute to extending the service life of boring tools.

Tool selection: For high-strength workpieces, select tools made of durable materials like carbide or cubic boron nitride (CBN). Tools with advanced coatings for improved heat and wear resistance should be considered for specialized applications.

Regular inspections: Examine boring tools on a regular basis to spot wear early. To find worn edges or tiny cracks before they cause tool failure, you can use magnifying instruments.

Optimized cutting parameters: To lessen tool stress, keep feed rates and cutting speeds balanced. Additionally, to prevent excessive tool wear, modify parameters according to the qualities of the material.

Effective coolant application: Directly apply high-pressure coolant to the cutting zone to reduce heat accumulation and efficiently remove chips. Utilizing cutting fluids with anti-friction qualities improves tool performance even further.

Vibration control: Utilize vibration-dampening equipment or tuned boring bars to stabilize the machining process and lower the risk of tool damage.

Sharpening and reconditioning: Professional sharpening can prolong the useful life of boring tools. Make sure that during the procedure, the right alignment and edge geometry are maintained.

Tool inventory management: Keep a supply of extra tools on hand to prevent downtime. Monitor tool lifespan and usage to schedule replacements on time.

Advanced solutions for common wear challenges

High-performance coatings: By increasing hardness and decreasing friction, contemporary tool coatings like titanium nitride (TiN) and diamond-like carbon (DLC) dramatically reduce wear. These coatings work especially well on abrasive materials or high-speed machining.

Cryogenic cooling: Liquid nitrogen is used in cryogenic systems to chill the cutting zone, improving heat control and extending tool life.

Real-time monitoring: Use sensors in CNC machines to keep an eye on vibrations, temperature, and tool wear. By warning operators of possible problems, these technologies allow for preventative actions to preserve tool performance.

Tool balancing: Make sure boring tools are properly balanced for high-speed operations to avoid vibrations and uneven wear.

FineTech Toolings: Your perfect partner for precision boring tools

One of the top brands of precision boring tools in Bangalore, FineTech Toolings, provides creative ways to combat wear and increase tool life. Their top-notch tools are made using cutting-edge materials and coatings to tackle even the most difficult machining tasks. By emphasizing performance and durability, FineTech Toolings enables manufacturers to attain remarkable outcomes while cutting expenses.

In today’s industry, boring tools are essential, yet wear and tear are unavoidable problems. Manufacturers may significantly enhance tool longevity and performance by comprehending typical wear difficulties, putting proactive maintenance plans into practice, and employing cutting-edge solutions. High-quality products from reliable manufacturers make it easy to achieve cost-effectiveness, efficiency, and precision. To propel your machining processes into the future, invest in the right tools and practices today!

Resource: Read more