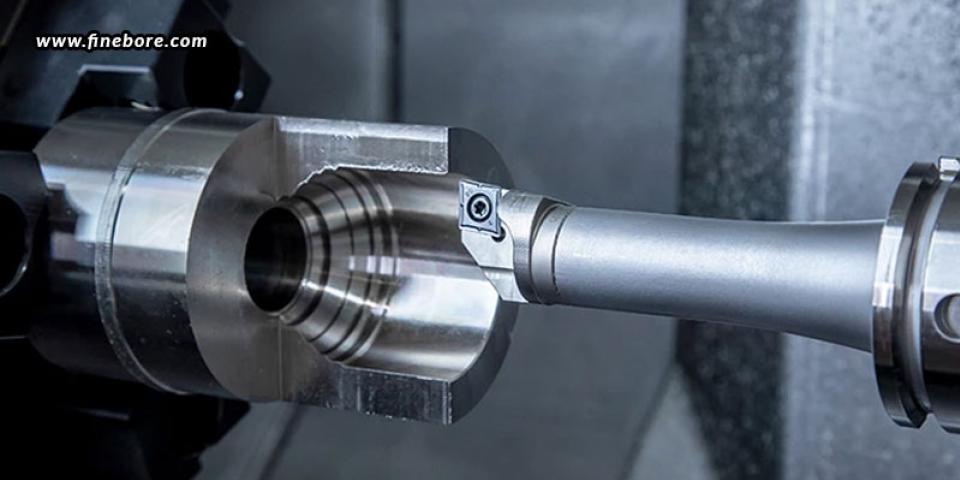

Precision machining requires the use of boring bars, and selecting the proper material for the boring bar is critical to obtaining the best possible performance, tool life, and cost effectiveness. Cutting speed, stiffness, wear resistance, and the kinds of materials that may be machined efficiently will all be significantly influenced by the material chosen. Carbide, ceramic, high-speed steel (HSS), and cermet are some of the most popular materials for boring bars. This blog will examine the several materials used to make boring bars, their benefits and drawbacks, and how to choose the best material for a given set of machining circumstances.

Carbide Boring Bars

Among the most popular materials for boring bars is carbide, and with good reason. This alloy, which is made of carbon and tungsten, is renowned for its remarkable wear resistance and hardness. Carbide boring bars are useful for both roughing and finishing operations, and they work especially well for high-speed machining.

Advantages

Carbide boring bars are perfect for high-performance machining because of a number of important benefits. They can handle harder materials like titanium, stainless steel, and other high-strength alloys without losing their edge thanks to their great wear resistance, which is one of their main advantages. Additionally, carbide can tolerate faster cutting rates than high-speed steel (HSS), which makes it ideal for high-efficiency, fast-paced machining operations, particularly in production settings when time is of the essence. Furthermore, carbide is stiffer during machining than HSS due to its significantly higher modulus of elasticity. By reducing tool deflection, this enhanced rigidity produces cuts that are more precise and accurate. Because of their hardness and resilience to heat, carbide tools also last longer, requiring fewer replacements and increasing productivity, especially in high-volume applications.

Drawbacks

Carbide boring bars have many disadvantages in spite of their considerable benefits. Their brittleness is a major drawback. Although carbide's hardness makes it perfect for cutting, it also increases the material's vulnerability to breaking from inappropriate handling or unexpected shocks. In some machining settings where impacts or vibrations are frequent, this brittleness may be a drawback. The increased expense of carbide tools is another disadvantage. The original and replacement costs of carbide boring bars are higher than those of HSS tools. However, their extended tool life, which eventually lowers downtime and the frequency of tool replacements, frequently justifies the higher price.

Best applications

For high-speed, high-precision machining of hard materials, such as heavy machinery, automotive engine parts, and aerospace components, carbide boring bars are perfect. They perform exceptionally well in applications that call for prolonged tool life and rapid material removal rates.

High-Speed Steel (HSS) Boring Bars

Another common material for boring bars is high-speed steel (HSS). Tungsten, molybdenum, chromium, and vanadium are added to steel to create HSS, an alloy that offers steel exceptional toughness and heat resistance. For general-purpose machining, HSS boring bars work well, and they work especially well in applications that call for moderate cutting speeds.

Advantages

Boring bars made of high-speed steel (HSS) have a number of benefits, most notably durability and affordability. Because HSS is stronger and more resilient than carbide, it is less likely to shatter under stress or shock. This is especially advantageous in applications where cutting conditions are unpredictable or interrupted. HSS tools are also less expensive than carbide alternatives, which makes them a sensible option for operations with less demanding machining needs or lower production quantities. Additionally, HSS boring bars are quite adaptable, working well with a variety of materials, including stronger steels and softer metals, and are useful for both roughing and finishing tasks. Additionally, HSS tools can be re-ground and have a longer usable life than carbide tools since they are easier to sharpen.

Drawbacks

Despite its many advantages, HSS tools have certain disadvantages. Their reduced wear resistance in comparison to carbide is a major drawback, especially when cutting at high speeds or with hard materials. Because of this, HSS is less appropriate for demanding jobs requiring frequent tool changes and significant wear. Additionally, HSS tools have a restricted cutting speed, which reduces their usefulness in high-speed machining settings where higher cutting rates are necessary, like in high-volume manufacturing. HSS tools often have a shorter tool life than carbide tools as a result, resulting in more frequent replacements and more downtime during machining operations.

Best applications

For general-purpose machining on softer materials like mild steel, aluminium, and polymers, HSS boring bars are perfect. They are frequently utilized in tool rooms, job shops, and applications involving moderate workloads and low to medium cutting rates.

Cermet Boring Bars

Ceramic and metal components are combined to create Cermet boring bars, which are usually composed of tungsten carbide or titanium carbide with a metallic binder. These tools are a fantastic option for high-speed cutting operations since they are made to provide a compromise between the toughness of metals and the hardness of ceramics.

Advantages

Cermet boring bars have a number of important benefits, particularly for applications requiring high performance. Their exceptional resistance to wear is one of their most remarkable qualities, which makes them very useful for cutting harder materials. Cermet tools require fewer tool changes since they maintain their cutting edge for a longer period of time than high-speed steel (HSS). Cermet tools are also renowned for offering superior surface finish, which makes them perfect for uses where precise, high-quality cuts are crucial. They stand out due to their exceptional thermal stability, which allows them to function well in hot conditions and be used to machine heat-resistant metals without sacrificing cutting effectiveness.

Drawbacks

Cermet boring bars have certain disadvantages in spite of their benefits. Cermet tools are less appropriate for tasks involving abrupt impacts or vibrations because, like carbide, they are very brittle and can shatter under severe shock pressures. Cermet is also less tough than some other materials, which limits its capacity to withstand more demanding cutting conditions, even though it is more durable than HSS. Because of this, cermet is less useful in applications requiring great toughness to endure difficult, demanding machining conditions.

Best applications

Cermet boring bars are frequently utilized in the aerospace and automotive sectors, especially for the machining of heat-resistant alloys and stainless steel.

Ceramic Boring Bars

Advanced ceramic materials like silicon nitride or aluminium oxide are used to make ceramic boring bars. These tools are widely recognized for their exceptional toughness and capacity to tolerate high temperatures without losing their cutting edge.

Advantages

There are a number of benefits to using ceramic boring bars, especially when working with really hard materials. They are perfect for applications where conventional tools may wear down fast because of their exceptional hardness, which enables them to keep sharp cutting edges even while machining hard workpieces and strong metals. Furthermore, compared to carbide or HSS tools, ceramic tools may function efficiently at significantly greater temperatures due to their superior heat resistance. They are therefore especially well-suited for machining processes involving high temperatures and speeds, where other materials could find it difficult to continue operating.

Drawbacks

Ceramic boring bars have significant disadvantages in spite of their benefits. Ceramics are very brittle and can break easily if handled improperly or subjected to shock loading during machining, which is one of the main concerns. This restricts its applicability in situations involving sudden tremors or collisions. Furthermore, although ceramic tools are excellent at keeping a sharp edge, their low toughness renders them brittle when used to machine materials that need to be robust or impact resistant.

Best applications

When high cutting speeds and temperature resistance are required for the high-precision finishing of hard materials like cast iron, superalloys, and hardened steels, ceramic boring bars are perfect.

A boring bar's material choice is essential to getting the best results from machining processes. Selecting the best tool depends on a number of variables, such as the kind of material being machined, the level of precision needed, and the working environment. Knowing the advantages and disadvantages of various boring bar materials is crucial for optimizing output and tool life, regardless of whether you're working with highly precise components, managing challenging materials, or seeking economical solutions. Selecting the material also impacts the environment, thus affecting sustainability. FineTech Toolings, as one of the most versatile precision boring bars manufacturers in Bangalore, offers a large selection of cutting-edge boring bars made to satisfy the varying demands of various industries. With a dedication to quality and performance, every product offered here guarantees the best outcomes from machining operations.

Resource: Read more