Diamond Like Carbon (DLC) is a

versatile material known for its unique combination of properties that mimic the

hardness and resilience of diamond, making it valuable in a wide range of

applications. Composed primarily of carbon atoms, DLC films exhibit a structure

that shares characteristics with both graphite and diamond, giving it

impressive strength, durability, and smoothness. DLC is increasingly being used

in industries such as electronics, automotive, medical devices, and more due to

its advanced mechanical, chemical, and thermal properties.

What

Is Diamond Like Carbon?

Diamond

Like Carbon refers to a family of amorphous

carbon materials that exhibit some of the typical properties of diamond. DLC

films are typically thin and can be deposited on various substrates to enhance

their wear resistance, reduce friction, and increase hardness. The key feature

of DLC is its hybrid structure, which contains both sp2 (graphite-like) and sp3

(diamond-like) carbon bonds. This combination imparts both hardness and

lubricity to the material, making it highly sought after in numerous

engineering and industrial contexts.

DLC coatings can be tailored to

achieve specific properties, such as high hardness, low friction, and chemical

inertness, depending on the ratio of sp2 and sp3 carbon and the presence of

additional elements like hydrogen or metals.

Key

Properties of Diamond Like Carbon

- Hardness and Wear Resistance: One of the standout features of DLC is its remarkable

hardness, which can approach that of natural diamond in some variations.

This hardness provides superior wear resistance, making DLC coatings ideal

for applications where parts are subject to heavy friction or abrasion.

Tools, bearings, and engine components often use DLC to extend their

operational life.

- Low Friction:

DLC has an inherently low coefficient of friction, meaning it reduces the

amount of wear and tear between moving parts. This property is

particularly valuable in applications such as automotive engines and

mechanical components, where reducing friction leads to higher efficiency,

lower energy consumption, and longer lifespan of parts.

- Chemical Inertness:

DLC is chemically inert, meaning it resists corrosion and degradation when

exposed to harsh environments. This makes it ideal for coatings used in

medical devices, chemical processing equipment, and electronics where

exposure to corrosive agents could otherwise damage the underlying

material.

- Biocompatibility:

DLC’s biocompatibility is one of its most important properties in the

medical field. DLC coatings are non-toxic and do not cause adverse

reactions in the body, making them ideal for use in medical implants,

surgical instruments, and prosthetics. This property, combined with its

durability, has led to DLC being used in hip joint replacements, stents,

and other medical devices that require long-term use.

- Optical Transparency:

In addition to its mechanical and chemical properties, some forms of DLC

are optically transparent. This allows DLC to be used as a protective

coating for optical devices, such as lenses and infrared windows, where

both durability and light transmission are essential.

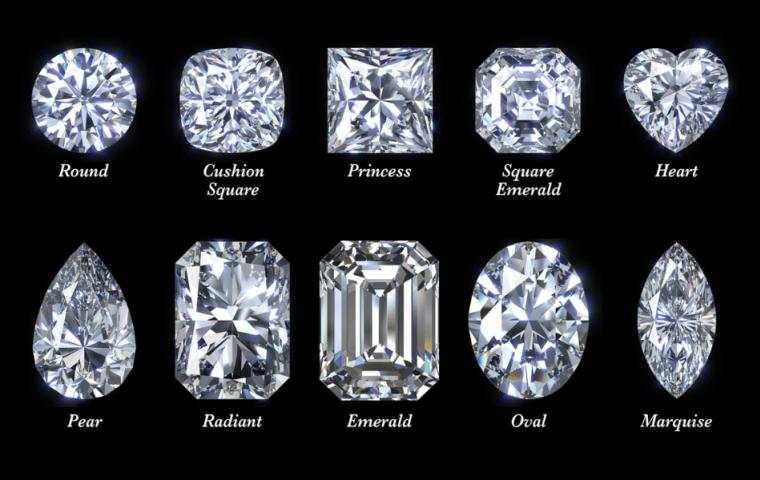

Types

of Diamond Like Carbon

There are several types of DLC

coatings, each with different properties, depending on the method of deposition

and the specific ratio of carbon bonding. The main types include:

- Hydrogenated Amorphous Carbon (a-C): This is the most common type of DLC coating, which

contains both sp2 and sp3 bonds along with hydrogen. The presence of

hydrogen helps to reduce internal stresses in the coating, making it

easier to deposit thicker films. It offers a good balance of hardness and

smoothness and is widely used in automotive and mechanical applications.

- Tetrahedral Amorphous Carbon (ta-C): This type of DLC contains a high percentage of sp3

bonds, resulting in an extremely hard coating that closely mimics natural

diamond. However, ta-C is more difficult to produce and can require more

advanced deposition techniques. It is typically used in applications where

extreme hardness and wear resistance are critical.

- Metal-Doped DLC:

In some cases, metals such as titanium or tungsten are added to DLC

coatings to modify their properties, such as increasing electrical

conductivity or enhancing adhesion to specific substrates. These coatings

are often used in electronics and specialized engineering applications.

Applications

of Diamond Like Carbon

Due to its unique combination of

properties, DLC has found use in a variety of industries:

- Automotive Industry:

DLC coatings are widely used in automotive components such as piston

rings, camshafts, and fuel injection systems. By reducing friction and

wear, DLC coatings help improve the efficiency and longevity of these

parts, resulting in better fuel economy and lower emissions.

- Medical Devices:

The biocompatibility and wear resistance of DLC coatings make them ideal

for use in medical implants and surgical tools. DLC-coated stents, hip

replacements, and other implantable devices benefit from the material's

durability and non-reactivity in the human body, reducing the risk of

complications.

- Electronics:

In the electronics industry, DLC coatings are used to protect sensitive

components from wear and corrosion. For example, hard disk drives (HDDs)

often employ DLC coatings on the disk’s surface to prevent damage from the

read/write heads during operation. DLC’s electrical insulating properties

are also leveraged in certain semiconductor applications.

- Cutting Tools:

DLC-coated cutting tools offer significant advantages in terms of hardness

and low friction. These tools can cut through materials more efficiently

and last much longer than uncoated tools, reducing downtime and increasing

productivity in industries like manufacturing and machining.

- Optics:

Optical lenses and windows, particularly those exposed to harsh

environmental conditions, benefit from DLC coatings. The material’s

durability and optical transparency allow lenses to maintain clarity while

resisting scratches and environmental damage.

The

Future of DLC Technology

As technology advances, new methods

for producing and applying DLC are constantly being developed, allowing for

more cost-effective and versatile coatings. DLC coatings are likely to play an

increasingly important role in the automotive, electronics, and medical

industries as they continue to seek high-performance materials with properties

like wear resistance, biocompatibility, and chemical inertness. The ability to

fine-tune DLC coatings for specific applications will undoubtedly lead to even

broader use in the coming years.

Get More Insights on Diamond Like

Carbon