The 3D printing has become phenomenally better over the course of time and in 2024, we all can't live without having something good printed for us by them. In the process, one of the most important things, that make these prints possible is having a good quality filament to begin with. So, how to find out what should be in a good 3d printing filament? In this post we are going to answer that. As, we all know, the caliber of filament has been playing an increasingly pivotal role in determining the outcome of end results. The most exceptional filaments are consistently exhibiting a harmonious blend of characteristics, properties and features that would ensure not only high quality prints but also user-friendly operation and longevity of the finished products.

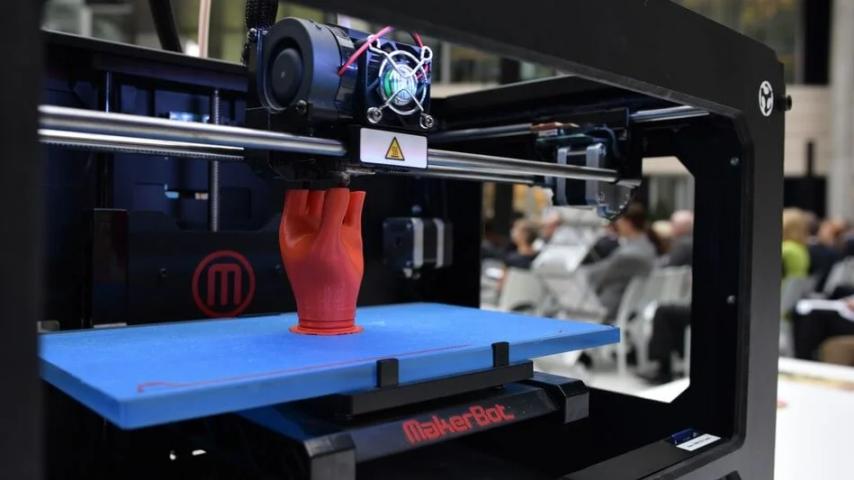

Dimensional precision stands out as a paramount feature of top-tier 3D printing filaments. The most reliable options are to maintain an unwavering diameter throughout the entire spool that holds them, typically adhering to a stringent tolerance of ±0.03mm or even less. It sounds astounding, but it's what it's. This good standards would help us get smooth and uninterrupted feeding into the printer's extruder, which has been resulting in more accurate prints and a significant reduction in instances of nozzle clogging or filament jamming.

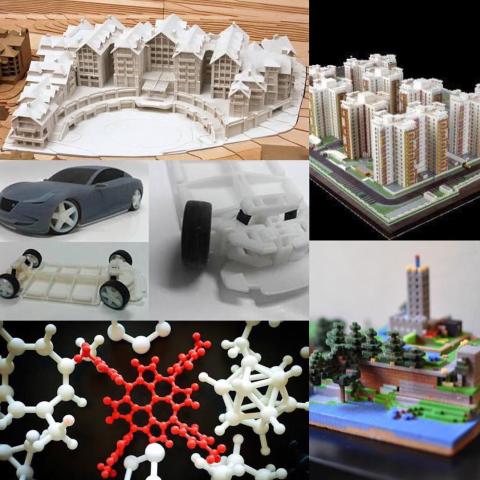

The mechanical attributes of premium filaments is equally crucial too to a greater extent. As the high-grade materials have been offering exceptional tensile strength and impact resistance, enabling the creation of robust and functional parts. These filaments could determine the minimal warping and shrinkage during the cooling phase, which has been vital for preserving the dimensional accuracy of printed objects. Even if we go further from that, the finest filaments have been providing superior layer adhesion, ensuring that the final products are structurally sound and resistant to delamination under various stress conditions.

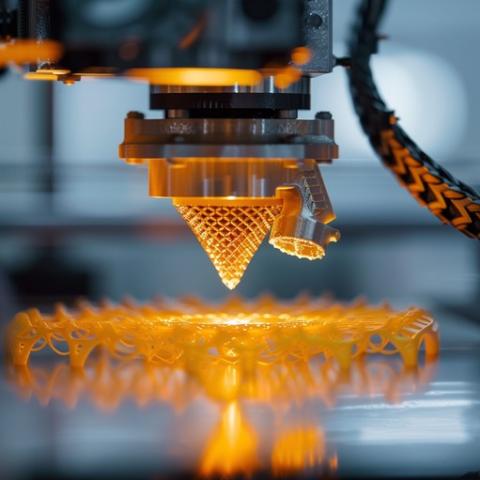

Thermal stability is another defining characteristic of superior filaments. The best options have been maintaining consistent performance across a broad spectrum of printing temperatures, offering flexibility in printing parameters and compatibility with a wide array of printer models. They would show and present a low tendency for stringing or oozing, which has been contributing to cleaner prints that require minimal post-processing work.

On the other hand, the surface quality of objects produced with high-caliber filaments is also notably superior. These materials would help us the creation of items with smooth surfaces and crisp details, faithfully reproducing even the most intricate features of 3D models. This attribute has been particularly valuable in applications such as prototyping and the production of aesthetic or display pieces.

However how can we go on about without talking about the environmental impact. These considerations have increasingly influencing the selection of premium filaments. Many top-tier options on the market could be biodegradable or manufactured from recycled materials, addressing growing concerns about the ecological impact of 3D printing. These eco-conscious choices have been maintaining high performance standards while offering a more sustainable alternative for environmentally aware users.

Dr. Rachel Thompson, a leading researcher in additive manufacturing materials at the Massachusetts Institute of Technology, has been emphasizing the significance of filament composition. She asserts, "The most exceptional filaments have been those produced with ultra-pure raw materials under rigorous quality control protocols. These filaments have been virtually free from contaminants and inconsistencies that could potentially compromise print quality or printer functionality."

But ARE THEY USER-FRIENDLY? Well, to cut the story short, the user-friendliness is another hallmark of superior filaments. They have been requiring minimal adjustments to printer settings and have been compatible with an extensive range of 3D printers. The best filaments have also been arriving neatly wound on the spool, substantially reducing the risk of tangling or breakage during the printing process.

Finally, the storage properties and shelf life of premium filaments have been critical factors THAT WE THINK YOU SHOULD CONSIDER SERIOUSLY TOO. High-quality options have been packaged in vacuum-sealed containers with desiccants to safeguard against moisture absorption. They have been maintaining their properties over extended periods when stored correctly, ensuring consistent performance even after prolonged storage durations. The most exceptional filaments for 3D printing have been those that offer a synergistic combination of dimensional accuracy, superior mechanical properties, thermal stability, excellent surface finish, environmental responsibility, material purity, ease of use, and extended shelf life. As 3D printing technology continues to evolve, these filament characteristics have been advancing in tandem, constantly expanding the horizons of what is achievable in the realm of additive manufacturing.