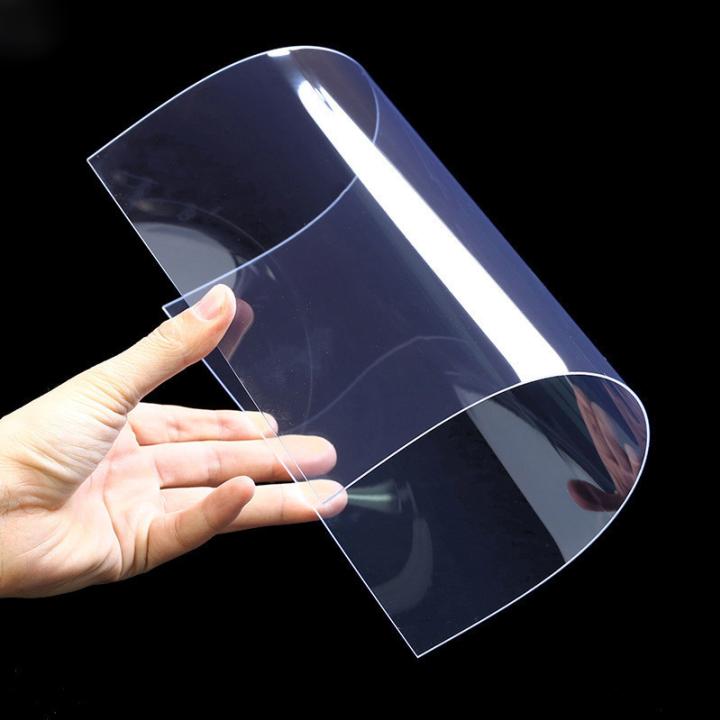

Cutting PETG sheet can be a straightforward process if the right tools and techniques are employed. Here's a detailed guide on how to effectively cut PETG sheet.

The first step is to gather the necessary tools. A fine-toothed saw, such as a coping saw or a jigsaw with a fine blade designed for plastics, is commonly used. For more precise cuts, a laser cutter or a CNC router can provide excellent results. Additionally, you'll need a measuring tape or ruler to mark the cutting lines accurately, and a sharp marking tool like a permanent marker or a scribe.

Before making any cuts, it's crucial to measure and mark the PETG sheet precisely. Use the measuring tape or ruler to determine the desired dimensions and mark the cutting lines clearly. Make sure the marks are visible and straight to ensure accurate cutting.

When using a saw, start the cut slowly and apply gentle pressure. Let the teeth of the saw do the work and avoid forcing the cut, as this can cause the sheet to crack or the cut to be uneven. For a jigsaw, select a slow speed to prevent overheating and melting of the material.

If you have access to a laser cutter, it offers a highly precise and clean cut. Set the appropriate power and speed settings based on the thickness of the PETG sheet. The laser beam will melt and vaporize the material along the marked line, resulting in a smooth and precise edge.

A CNC router can also provide consistent and accurate cuts. Program the router with the desired cutting path and ensure the bit is sharp and suitable for cutting plastics.

Another method for cutting PETG sheet is scoring and snapping. Use a utility knife or a scoring tool to make a shallow groove along the cutting line. Then, apply pressure on either side of the score to snap the sheet along the line. This method is suitable for thinner PETG sheets.

It's important to note that regardless of the cutting method used, proper safety precautions should be taken. Wear safety glasses to protect your eyes from flying debris and ensure a well-ventilated area to avoid inhaling any fumes.

After cutting, you may notice some rough edges or burrs. These can be smoothed and refined using sandpaper or a file. Start with a coarse grit and gradually progress to a finer grit to achieve a smooth finish.

Let's take an example of cutting a PETG sheet to make a custom-sized window panel. First, measure the dimensions of the opening where the panel will be installed. Mark the cutting lines on the PETG sheet accurately. Using a jigsaw with a fine blade, make the cut along the marked lines. After the cut, use sandpaper to smooth the edges and ensure a snug fit in the window frame.

Another example could be cutting PETG sheet for a DIY project, such as a custom enclosure. In this case, a laser cutter or CNC router might be preferred for the complex shapes and precise cuts required.

In conclusion, cutting PETG sheet can be accomplished successfully with the right tools, careful measurement, and appropriate techniques. Whether for a simple or complex project, following these guidelines will help you achieve clean and accurate cuts, allowing you to make the most of this versatile material.